Temperature variation is bad. It cracks the pavement, breaks bridges, and it ruins results in precision manufacturing and engineering.

In precision engineering, temperature variation is the single greatest source of error. This includes and is not limited to diamond turning machines, interferometers, atomic force microscopes, and profilers as well as many other types of metrology equipment. The good news is that error caused by thermal variation can be significantly decreased. Simply use a Praecis Air Temperature Control Unit to tame the variations in temperature.

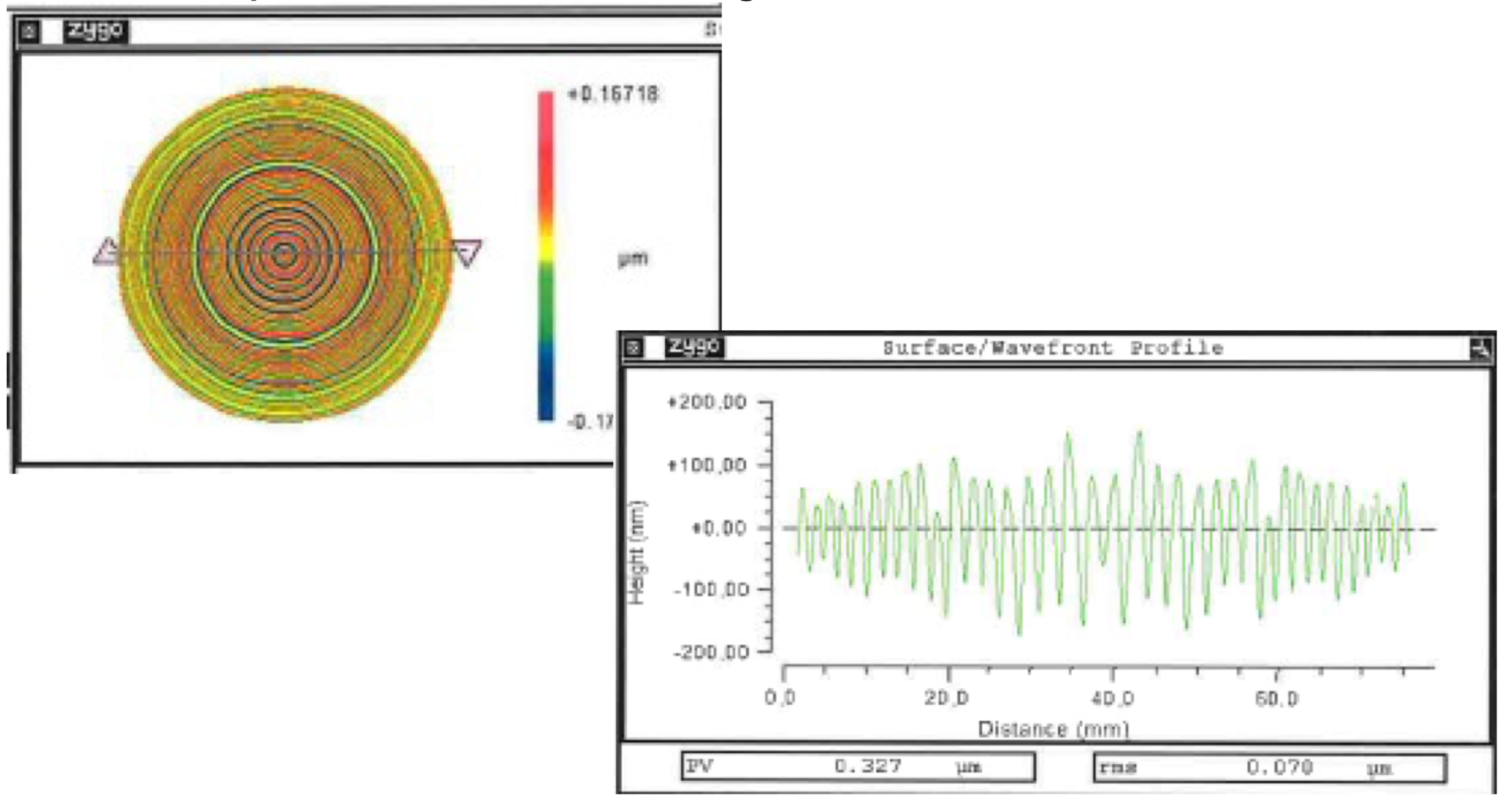

Take a look at the figure below. It is an interferometric analysis of the flatness of a part cut over the course of 5 hours while the room temperature cycled by +/- 1 ºC with a period of 18 minutes. As you can see, the resulting part profile reflects the influence of temperature changes with an amplitude of 0.327 micrometers p-v.

To eliminate the waviness, temperature control was used:

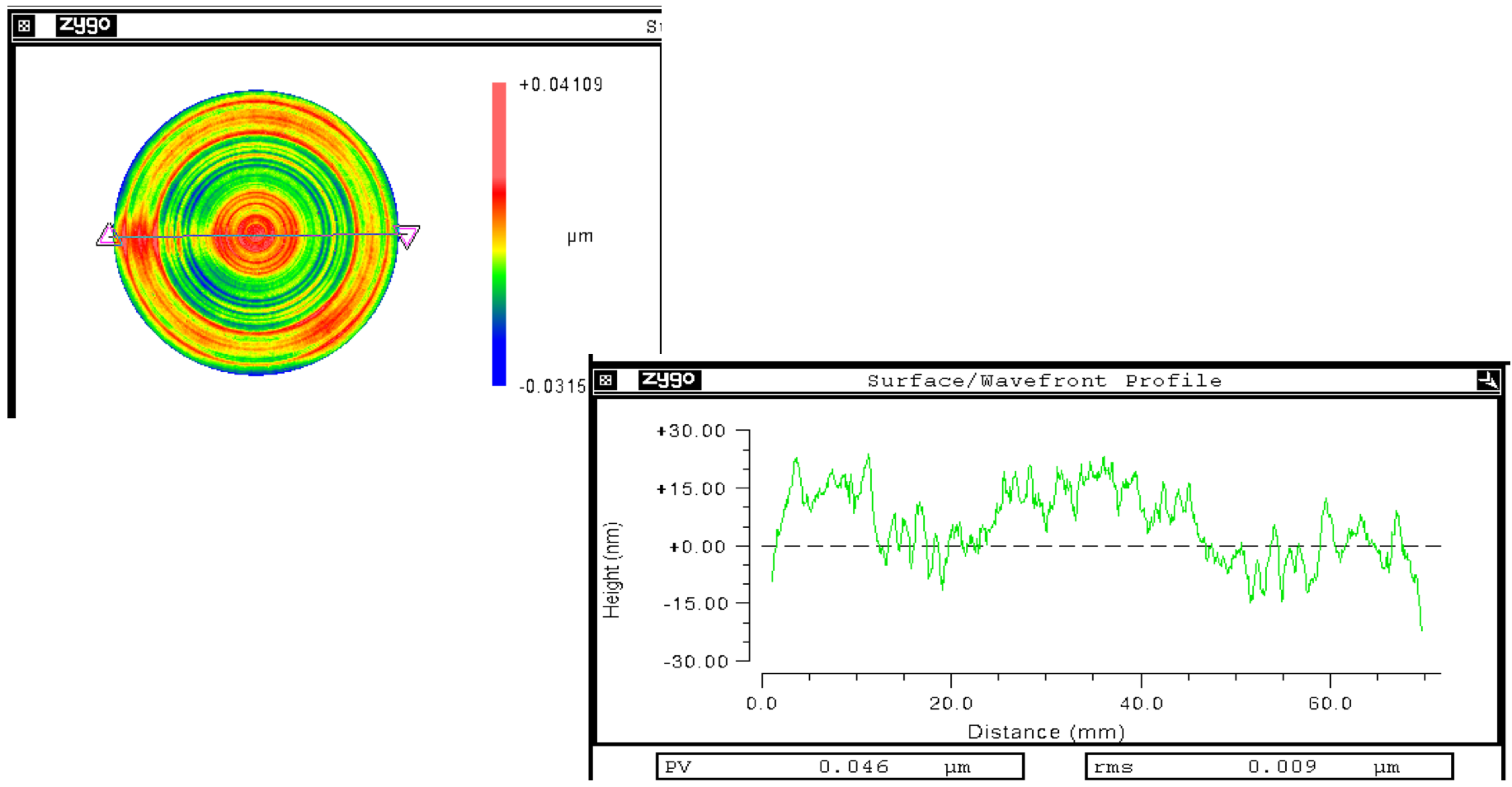

The next figure displays the result of cutting the same part under identical conditions -- but with +/- 0.1 ºC temperature control.

The waviness is gone, and the part flatness was improved by a factor of 7 to 0.046 micrometers PV.

Precision temperature control is the most cost effective way to improve machine performance and reduce errors caused by thermal effects. In the chart above basic temperature control was improved from ±1.0 ºC to +/- 0.1 ºC for the same part cut. The resulting cut showed error reduction by a factor greater than 7.

Don’t let thermal variation bite you. Bite back with high precision temperature control. By using products like the Praecis Environment you can essentially eliminate error by up to a factor of 10 or greater.